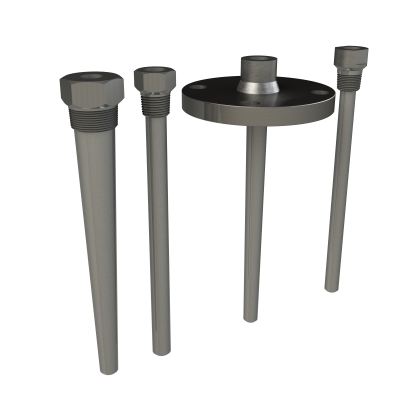

Welded thermowell and drill barstock thermowell

Tubular or welded thermowells are made from tubes and are suitable for applications without significant stress.

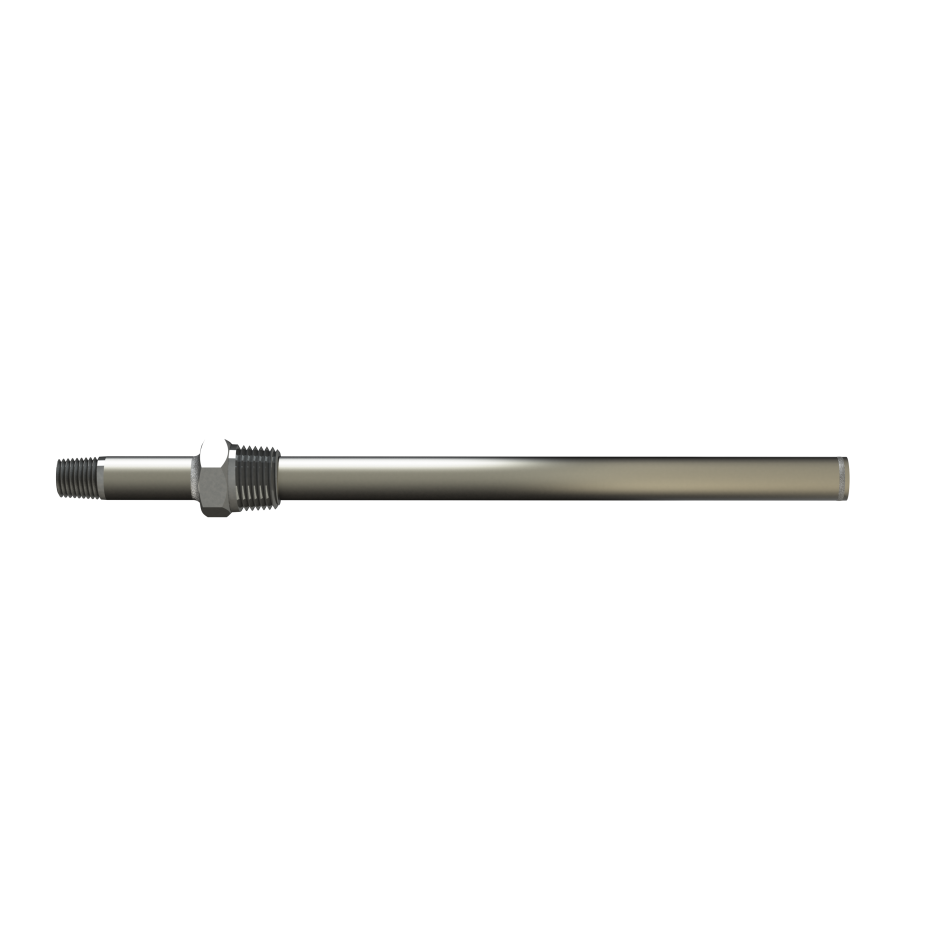

Drill barstock thermowells are machined from a barstock; they are more resistant and are suitable for severe process conditions in terms of high temperature and pressure or high flow rate.

GENERAL DATA

- Material: Standard: 304L / 316L stainless steel, others according to your application.

- All types of fluids in contact

- Coating possible for corrosive fluids

| Drill barstock thermowell | Welded thermowell | ||

|---|---|---|---|

| Instrumentation connection | NPT tapped - other on request | Threaded / NPT tapped - other on request | |

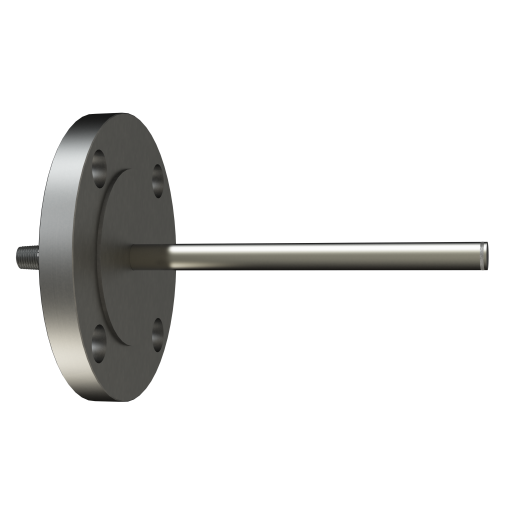

| Process connection | Threaded, with flange (tight welding, full penetration welding or machined from barstock), to be soldered, clamp |

Threaded, with flange, to be soldered, clamp | |

| Thermowell shape | Straight or conical, with or without restriction | Straight | |

| Immersion length | According customer specifications | ||

| Inner and outer diameter | According application | ||

| Maximum pressure and temperature of the process | According to the thermowell execution (dimension, material, nominal pressure of the flange) and to process conditions (flow, fluid speed) | ||

| Stress calculation | According to ASME PTC 19.3 TW standard recommended for critical applications |

- | |

If you do not find the answer you are looking for, please contact us either by phone at +33 (0)5.59.30.85.20 or via the contact form. We will respond as soon as possible.

A welded sensor pocket is made from a tube that will be welded at the bottom. It is suitable for low to medium process demands.

A thermowell drilled from a barstock is free of solder (excluding any welding of the flange) and is suitable for medium to high process demands.

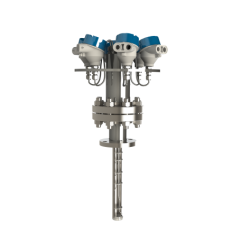

A probe or the bulb of a thermometer are often placed in a thermowell, also called a sensor pocket, to protect them from industrial fluids (corrosive, abrasive, high-pressure, high-temperature, high-speed, etc.) they measure the temperature. It is therefore the thermowell which is directly in contact with the fluid to be measured; it will be sized to withstand the characteristics of the fluid considered.

The choice of material is essential for a thermowell because it is in direct contact with the fluid. It is therefore necessary to take into account the possible phenomena of corrosion and the temperature of the fluid. We define thermowell geometry based on ASME PTC 19.3 TW. The latter takes into account the resistance of the well to the static pressure and the resistance to vibration generated by the flow so as to avoid resonance peaks.

The temperature measuring point may be positioned at any point representative of the value to be measured provided that it has no influence on the process and does not interfere with the flow measurement, if appropriate.

Attention: in the case of a flow measurement, the temperature sensor will always be positioned according to the recommendations of the ISO5167 standard; it specifies the straight upstream and / or downstream lengths that must be respected to position the thermowell relative to the flow measurement element so that it does not influence the measurement.

The immersion length of the thermowell and the probe is also very important to have a precision corresponding to the requirements of the process. At first approach and for a standard application, the end of the thermowell must be in the central third of the pipe. But the pressure and the velocity of the fluid with which it is in contact must be taken into account and the right compromise between length of immersion, resistance and accuracy of measurement of the temperature must be found. Only a specialist in instrumentation such as Deltafluid can advise you in the possible choices. Do not hesitate to consult us for a thorough study of your need.