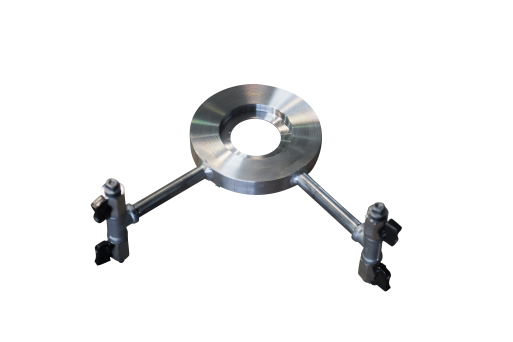

With integrated pressure taps for ease of installation

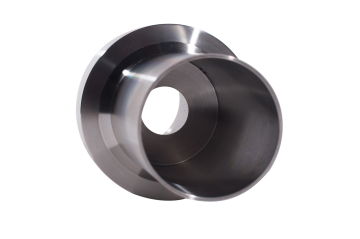

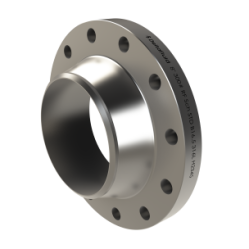

The monoblock diaphragm and the ISA1932 monoblock nozzle are made from a solid round. The pressure taps are directly machined in the monoblock. They can be simply machined (pressure tapping holes) or supplied with nipples to connect directly to your installation. This type of diaphragm or nozzle has the advantage of being simple to install: simply mount it between single flanges or weld directly on the pipe for a version to be welded.

All types of edges (sharp-edge, conical, quarter-circle, eccentric, segmental and multi-hole) can be made in a single-piece version. Flanged or corner pressure taps can be made in monoblock version.

For the technical characteristics of the measuring orifice, refer to the characteristics of the selected element (sharp-edge, conical, quarter-circle, eccentric, segmental or multi-hole, ISA1932 nozzle).

If you do not find the answer you are looking for, please contact us either by phone at +33 (0)5 59 30 85 20 or via the contact form. We will respond as soon as possible.

A monoblock diaphragm has the advantage of having integrated pressure taps (supplied with pre-machined or connecting nipples). Thus, it is easy to install: just mount it between single flanges. The monobloc diaphragm can also be designed for soldering mounting directly on the pipework.

All types of orifices (sharp-edge, conical, quarter-circle, segmental, eccentric and multi-hole) can be made in a single-piece version.