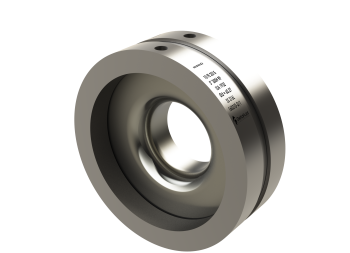

Nozzle

The most appropriate solution for high flow rates / steam flow rates

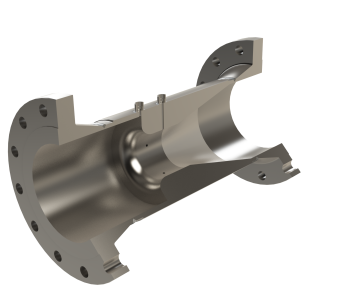

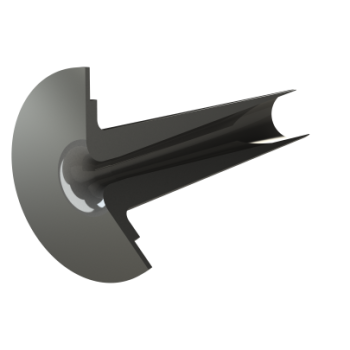

The nozzle has a radiated input and is therefore suitable for fluids flowing at high speed. Unlike an orifice plate whose edge could be damaged, the ISA 1932 nozzle and the long radius nozzle according to the names of the standard are quite suitable for these applications.

For corrosive or aggressive fluids, the surface in contact with the fluid can be covered with a special coating to improve their lifetime.

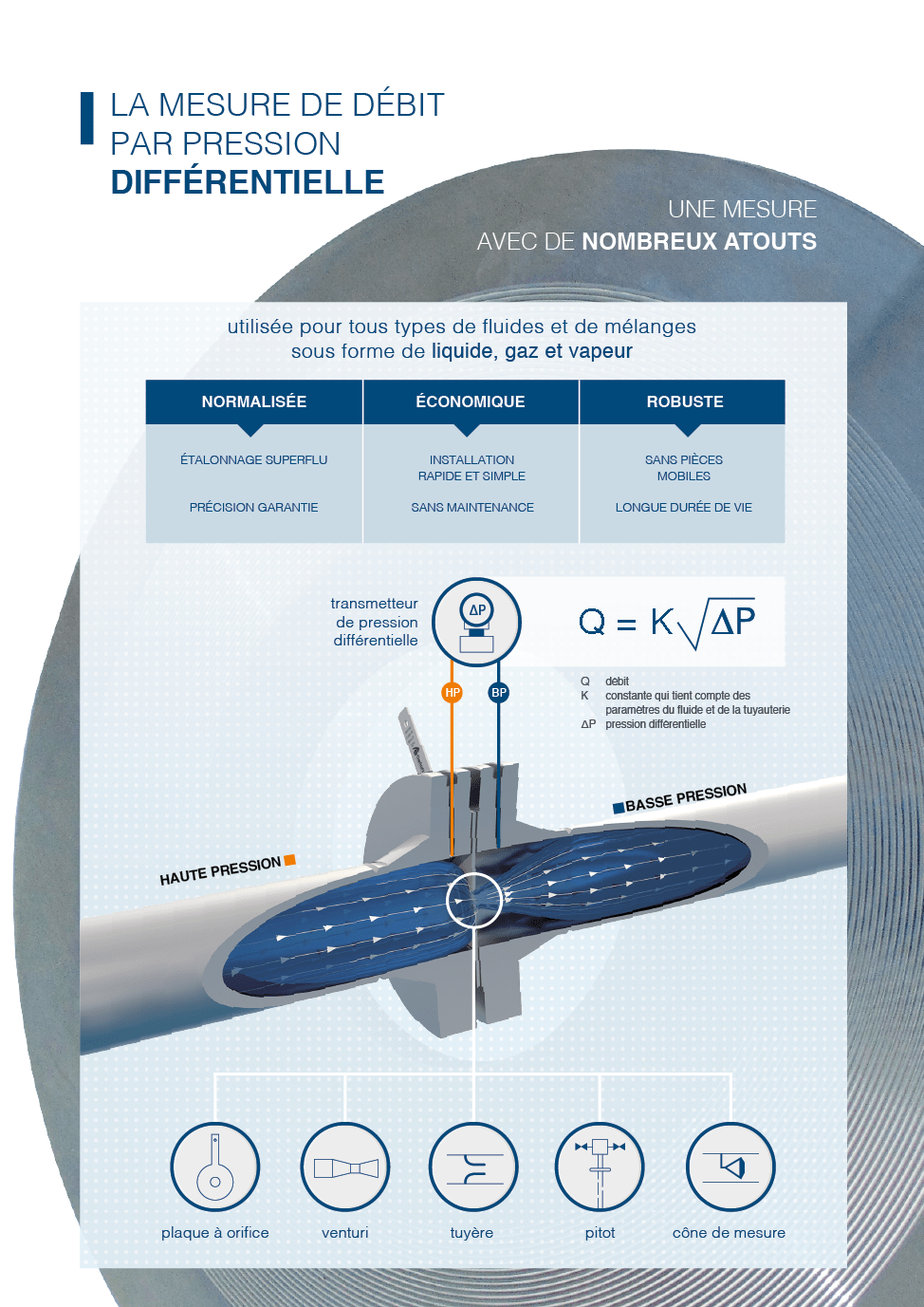

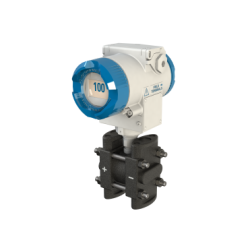

The principle of the differential pressure flow measurement is to insert in a circular pipe a restriction which generates a pressure difference between the upstream and the downstream of this restriction.

The measurement of this pressure difference (called ΔP) is transformed by a differential pressure sensor into a 4-20 mA signal and then translated into a flow rate according to the law:

Q being the flow

K a constant that takes into account the fluid parameters, the viscosity, the roughness of the pipework, the density of the fluid, etc.

Δp the differential pressure (upstream pressure - downstream pressure).

The differential pressure element considered here is the nozzle.

There are other types more or less adapted to the characteristics of your process. It's about choosing the best solution in terms of measurement quality, size and price. That is why we are at your disposal to bring you all the information on this subject and help you in your selection.

This table is a tool to help select the flow measurement primary element.

Depending on the type and characteristics of the medium to be measured, you will have a first idea of the differential pressure device adapted to your application.

Attention, as any first approach, it is imperative to validate the choice by a calculation made by our specialized design office.

For the calculation, we need information about your process.

If you do not find the answer you are looking for, please contact us either by phone at +33 (0)5 59 30 85 20 or via the contact form. We will respond as soon as possible.

A nozzle is generally chosen to measure high flow rates at high speed and in particular steam flow rates. A venturi tube allows a low permanent pressure drop and requires shorter straight lengths than the nozzle; it will therefore be chosen if the pressure of the fluid is low and if space is an important issue. There is also the venturi-nozzle which is a mix of both devices: it has a curved inlet like the nozzle, an outlet with a divergent like the venturi.

In any case, do not hesitate to ask us for the product that best suits your application.