Simple and economical solution

GENERAL DATA

- Standards: Element based on R.W. MILLER or ISO 5167.

- Mounting between flanges: ISO PN 2,5 to PN 420, ASME 150 # to 2500 #, others on consultation.

- Material: Standard: 304L / 316L stainless steel, others according to your application.

- Fluid: liquid, gas, steam.

- Diameter of pipes: all sizes.

-

Orifice diameter: dimensioned according to the fluid, to the pressure drop to be achieved and to the flow going through the restriction.

-

Plate thickness: calculated taking into account the pressure drop generated by the plate and the diameter of the pipework to prevent plate deformation. MORE DETAILS (FAQs)

-

Noise: control of the estimated noise level at 1 m. In case of high noise level, refer to the multi-hole plate.

-

Cavitation: For liquids, the cavitation level is checked for each plate. In the presence of cavitation, a multi-stage restriction orifice alternative may be proposed depending on the operating conditions of the restriction. LEARN MORE

-

Critical regime (choked flow or choking cavitation) : if the fluid reaches its maximum speed when passing the restriction, its flow can not increase. A multistage solution can be proposed depending on the operating conditions of the restriction. NEED MORE EXPLANATIONS?

If you do not find the answer you are looking for, please contact us either by phone at +33 (0)5.59.30.85.20 or via the contact form. We will respond as soon as possible.

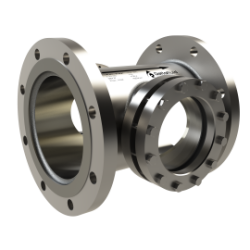

A restriction orifice is used to limit a flow rate or to reduce a pressure in a pipe. It advantageously replaces a simple valve: simpler, more economical, more robust and maintenance free.

This is a calibrated orifice placed in a pipe. It is calculated according to your technical specifications in order to reach the desired pressure or flow value while respecting the integrity of the plate and the piping.

MORE DETAILS? (FAQs)

Depending on the flowrate and the flow conditions in the pressure reducer, the noise level of the fluid when passing through the restriction may be beyond the permitted standards. Thus, the multi-hole orifice plate allows the noise level to drop while maintaining the same pressure reduction properties.

LEARN MORE about the noise level limitation (see FAQs)