Fluid Mechanics design departement

Our Fluid Mechanics design department specializes in the custom design of instrumentation devices for flow measurement, temperature measurement and flow / pressure limitation (restriction orifice).

➮ Thanks to our know-how and expertise, we can advice you on the instrumentation of your processes and develop a tailor-made solution for your application.

➮ All our devices are designed, manufactured, controlled and tested to meet the requirements of the relevant standards and building codes.

➮ The standards for each area of activity are described below.

➮ Some of our equipment is subject to the european Pressure Equipment Directive PED 2014/68/UE depending on the fluid used, the volume of the equipment and the maximum permissible pressure (> 0,5 bar). In such cases, calculations are carried out and the corresponding certificates are delivered with the technical documentation.

➮ Building codes and standards applicable to our studies are also available here.

Flow Measurement

For the studies in flow measurement, we provide :

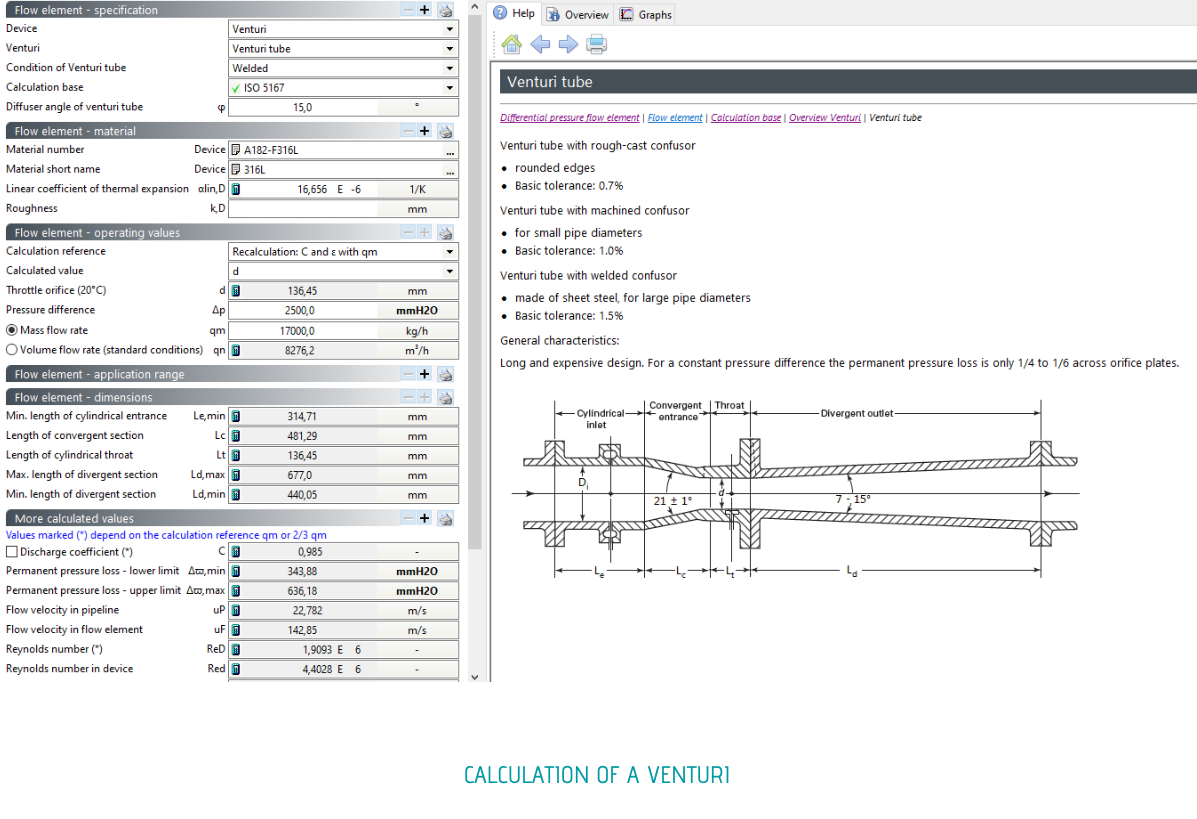

- Calculations according to international standards: ISO 5167-1 to 6, ISO / TR 15377, ASME MFC-3M, R.W. MILLER, ASME MFC-14M, ISO 9300, ASME PTC 19.5, ASME PTC 6, ISO / TR 11583.

- The choice of measurement technology for optimum measurement accuracy.

- The density correction for gases and compressible fluids.

To provide us with precise information on the fluid to be measured and on your process, we advise you either :

- to enter and validate data on our SIZEWELL pre-sizing tool. We will then receive the information directly (and any comments you may have) which will enable us to proceed and check.

- to fill in the information sheet which enables us to calculate accurately according to the appropriate standard.

Flow limitation & pressure regulation

For flow limitation and pressure regulation studies, we perform calculations with :

- Consideration of cavitation factor, critical flow, noise level, change of state of the fluid.

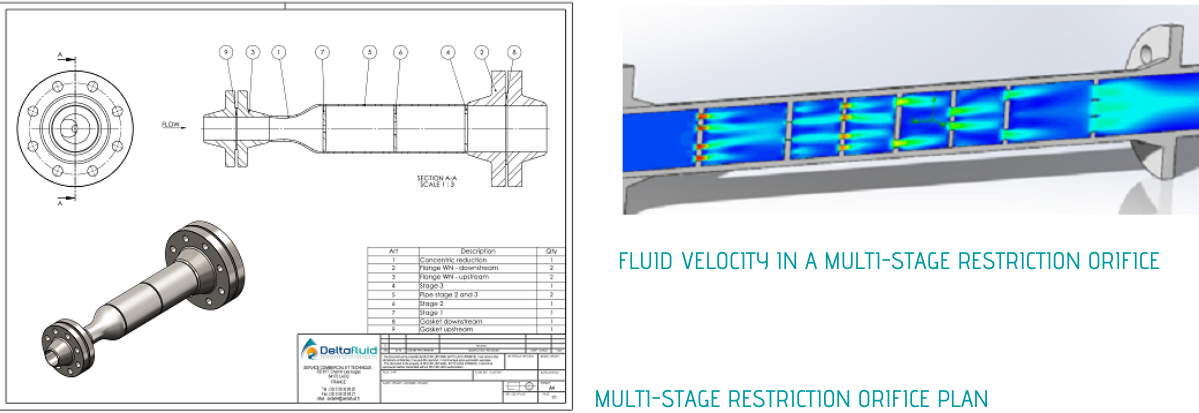

- Restriction orifice design optimisation : single hole, multi holes, multi stages.

- If needed, finite element calculation to check the mechanical resistance of the devices.

Temperature measurement

For temperature measurement studies, our analysis is based on the following criteria :

- The choice of the measuring technology according to the requested accuracy and response time.

- Calculations according to ASME PTC 19.3 TW standard carried out to guarantee the thermowell is mechanically resistant to the constraints of the process.

Our design department can provide you with the following elements in our fields of activity:

Flow measurement

- Drawing of the proposed devices.

- Layout plans and system modeling in your process.

Restriction orifices

- Drawings of single and multi-stage restriction orifices.

- Flow Simulation (CFD) to validate the results of analytical calculations in complex cases.

Temperature measurement

- Drawings of sensors and thermowells.

- Layout diagrams

- Flow simulations to evaluate the thermal behavior of the fluid and the materials in contact.

Deltafluid is present for you throughout the project and helps you from the definition of your need to delivery and commissioning.

PRE-SALE

- Feasibility study

- Choice of the solution

- Pre-calculation

- Dimensional drawing

- Price study & deadline

- Technical & commercial offer

PROJECT MANAGEMENT

Detail plans

Detail plans- Technical documentation (drawings and final calculation notes)

- Material purchase

- Manufacturing

- Control & test

- Packaging

- Final documentation

- Shipment

AFTER SALE

- Helpline

- Warranty

- Expertise

The Fluid Mechanics engineering department offers on-site services:

- Commissioning assistance: it involves checking the installation of our devices in the installation, checking the settings and validating the measurements.

- Installation expertise: we are able to verify the use of our devices on an existing installation, to check their wear and to advise you on the optimal operation of our measuring systems.

- Preventive maintenance: our devices generally require little maintenance. However, to ensure good measurement accuracy and good operation over time, the equipment should be checked periodically. We are able to advise you for the maintenance of our devices.

If you do not find the answer you are looking for, please contact us either by phone at +33.(0)5.59.30.85.20 or via the contact form. We will respond as soon as possible.

Of course. We are at your disposal to carry out studies of calculation and dimensioning of the flow measurement primary elements and of restriction orifices according to the corresponding standard; to know, for example, if you need a single or multi-stage restriction orifice and how many stages if necessary.

You may need this information at the pre-project stage to anticipate the footprint of the equipment or also to have the parts manufactured in a workshop nearer to you (this is especially valid for international projects on parts that can be bulky and heavy so expensive to transport).

Be careful, however, to meet the criteria of the standard for the manufacture of products: otherwise, the accuracy of the results can absolutely not be guaranteed.

Calculations for the sizing of the flow measurement elements were carried out during the study of your installation. The diameter of the orifice has been selected and manufactured according to your input data.

The data then used may have changed during the operation of the installation (new flow for example) while the diameter of the orifice is constant; the calculation must then be repeated with the new data to determine if there is a need for recalibration of the differential pressure transmitter. An adjustment of the transmitter may indeed be necessary for a good flow measurement. From this new calculation depends the accuracy of the measurement.