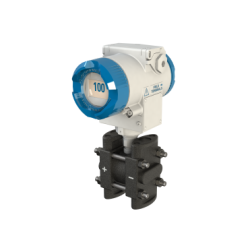

Suitable for large flow rates with low permanent pressure drop

GENERAL DATA

- Standards: ISO 5167-1 & 3, ASME MFC-3M.

- Solder (BW) or flanged connection

- Material: Standard: carbon steel, stainless steel, others according to your application.

- Fluid: liquid, gas, steam. Diameter of pipes: from 65 to 500 mm.

- Accuracy> 1.2% of max flow.

- Repeatability of the measurement: 0.1%.

- Pressure taps at the neck: annular chamber or individual plugs connected in "triple T".

| ISO 5167-1&3 & ASME MFC-3M | ||

|---|---|---|

| ReD | Reynolds number in pipework | 1,5.105 ≤ ReD ≤ 2.106 |

| D | Pipe interior diameter | 65 mm ≤ D ≤ 500 mm |

| d | Orifice diameter | d ≥ 50 mm |

| β | d/D | 0,316 ≤ β ≤ 0,775 |

| Ra | Upstream face and throat roughness | Ra ≤ 10⁴.d |

| b | Length of the cylindrical throat | b = 0,7.d à 0,75.d |

| φ | Diverging angle of exit | φ ≤ 30° |

If you do not find the answer you are looking for, please contact us either by phone at +33 (0)5.59.30.85.20 or via the contact form. We will respond as soon as possible.

A venturi-nozzle has a rounded inlet like the nozzle, an outlet with a divergent like the venturi. Thus, it is really a mixture between the nozzle, which will generally be chosen to measure high flow rates at high speed and in particular steam flow rates and a venturi tube allowing a low permanent pressure drop and requiring lower straight lengths than the nozzle. Thus, it is suitable for measuring large flows and when the pressure of the fluid measured is low.

In any case, do not hesitate to ask us for a study to select the product that best suits your application.