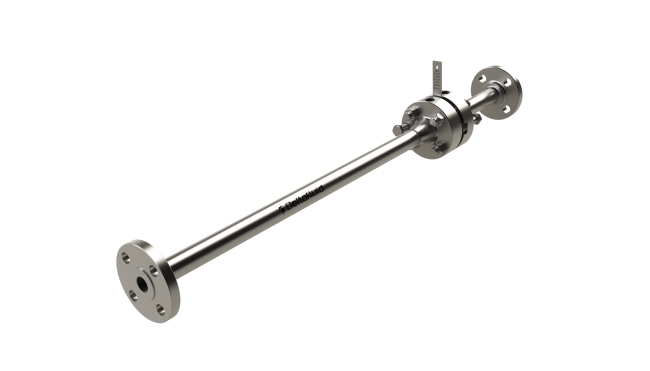

Meter run

Complete and flexible measuring element to facilitate on-site installation

GENERAL DATA

- Standards: ISO 5167-1 & 2, ASME MFC-3M or ISO / TR 15377.

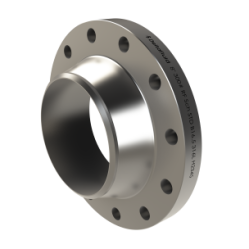

- Mounting of the primary element between flanges: ISO PN 2.5 to PN 420, ASME 150 # to 2500 #, others on consultation.

- Solder (BW) or flanged connection

- Material: Standard: carbon steel, stainless steel, others according to your application.

- Fluid: liquid, gas, steam.

- Diameter of pipes: from 25 to 300 mm (for ease of assembly).

- Precision: depending on the chosen measuring element

- Repeatability of the measure: 0.1%

THE FLOWMETER INCLUDES:

- the desired orifice (orifice plate, nozzle)

- the flanges to fix the orifice

- upstream and downstream straight lengths in accordance with the chosen standard

ASSEMBLY AND ASSEMBLY DATA:

- The design, manufacture and assembly are carried out in our workshops in compliance with the standards (upstream and downstream pipe roughness, centering of the primary element, circularity of the piping, upstream and downstream straight lengths) in order to achieve optimal measurement accuracy.

CHARACTERISTICS :

- orifice plate - see corresponding technical data sheet

- nozzle - see corresponding technical data sheet

- upstream, downtrseam straight lengths, roughness and circularity of the tubes, centering measuring element - see accuracy in the corresponding standard

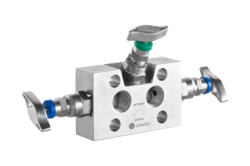

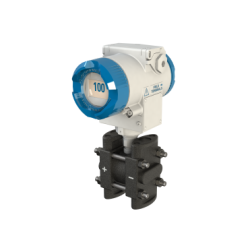

ACCESSORIES :

- manifold - see corresponding technical data sheet

- differential pressure transmitter - see corresponding technical data sheet

You can find below our most frequently asked questions / answers.

If you do not find the answer you are looking for, please contact us either by phone at +33 (0)5.59.30.85.20 or via the contact form. We will respond as soon as possible.

When can a measurement section be used?

A measuring section is equipped with upstream and downstream pipe lengths in compliance with the criteria of the standard (roughness, circularity ...) to ensure good measurement accuracy.

The measurement section is the compromise, from equipment and accessories point of view, between:

- integrated orifice (special flanges, DN ≤ 40, pressure taps in the corners)

- the high-precision measuring tube (complete tube with corner or flange pressure taps, manifold, pressure transmitter, temperature sensor if applicable)

But the respect of the standard for all the criteria influencing the measurement accuracy (upstream and downstream tube lengths, roughness, circularity) is the same for these 3 devices.