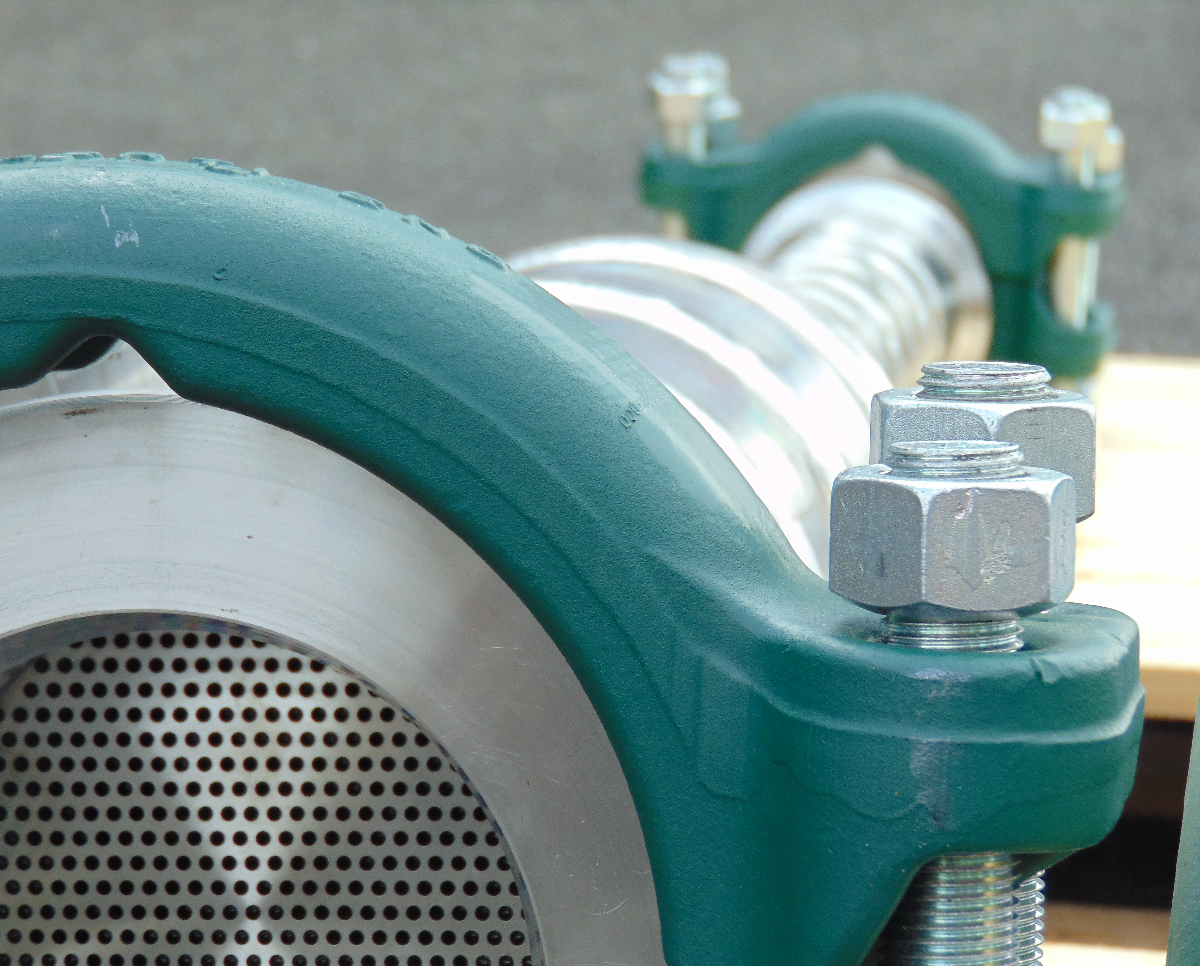

To connect multiple pipe elements

The flanges on the measuring elements and the piping allow easy assembly and disassembly unlike the welded assembly.

Different types of flanges are available to meet all standards, all requirements in all areas of activity.

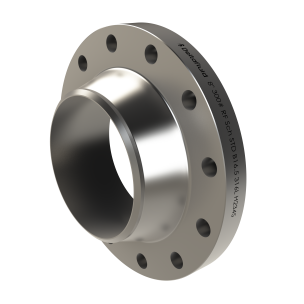

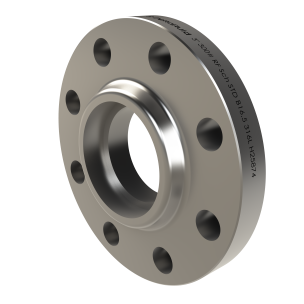

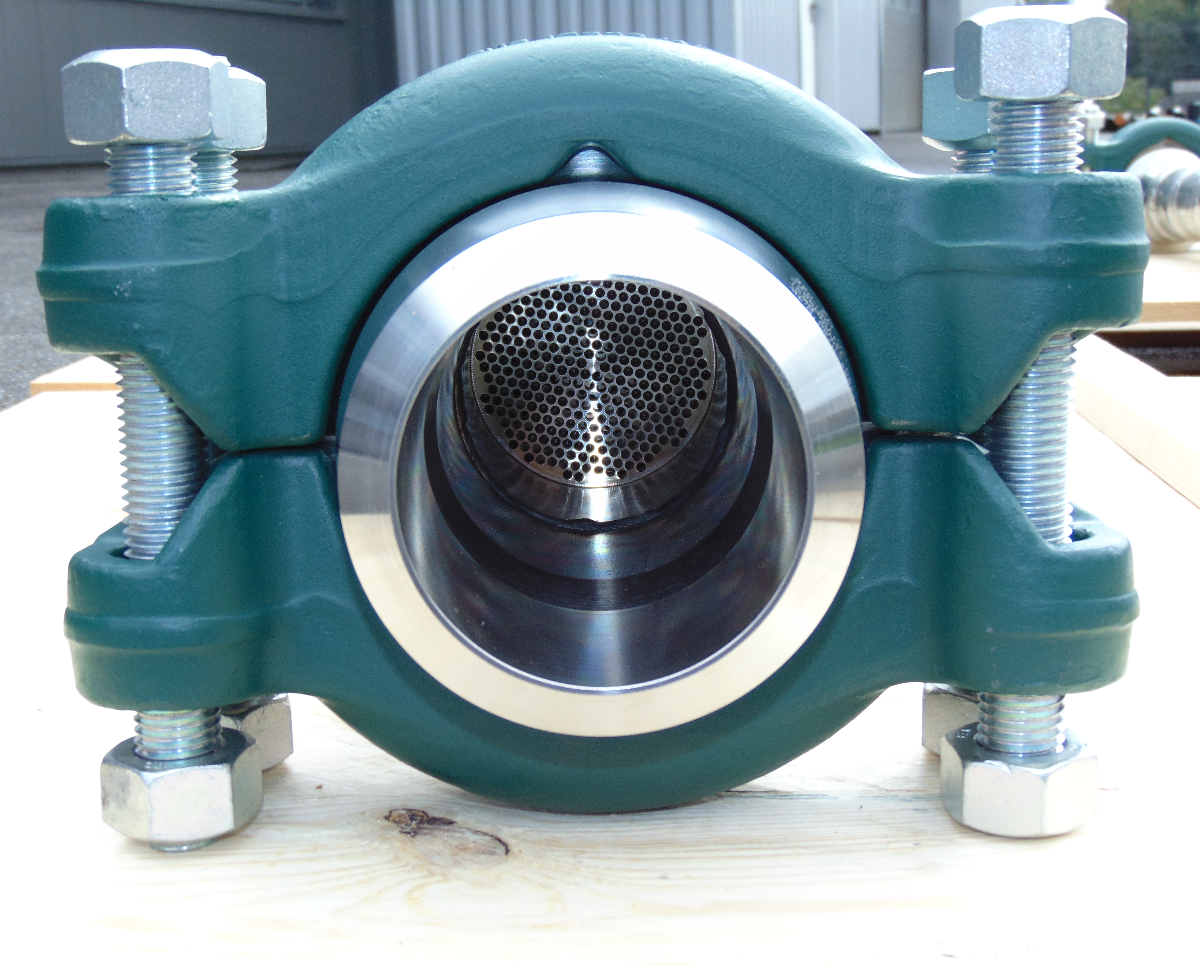

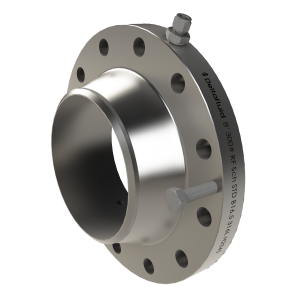

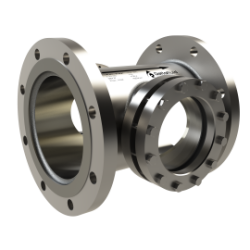

Orifice flanges :

They are used for flow measurement with orifice plates. They allow, thanks to the integrated pressure taps, to recover high and low pressure (Δp).

MAIN FEATURES

- Standards: ASME B16.5, B16.36, B16.47, MSS SP-44, API6B.

Corresponding flanges: welding neck, orifice welding neck, slip on, socket welding, blind.

Operating pressure: ASME 150 # to 2500 # or API 200 PSI to 20,000 PSI. - Standards: NF EN 1092-1, NF EN 1759-1.

Corresponding flanges: flat welding flange (type 01), solid flange (type 05), butt flange with butt weld (type 11), ...

Operating pressure: ISO PN 2.5 to 420. - All types of faces: RF, RTJ, with interlocking, other faces of seal according to your application.

- Diameter: DN1 / 4 '' to 24 '' - up to 60 '' on request.

- Material: standard: carbon steel, stainless steel, duplex, others according to your application

- Thickness to be specified.

- Schedule: 5 to XXS.

If you do not find the answer you are looking for, please contact us either by phone at +33(0)5 59 30 85 20 or via the contact form. We will respond as soon as possible.

The choice of flanges depends on the pressure (class of flange) and the connection provided on the pipe.

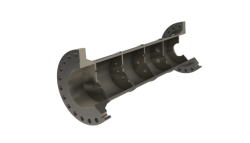

It should be noted that the welding neck flange is the only one that has a circular weld while the other flanges only have corner welds. It is therefore recommended for more demanding applications (for 2500 # for example).

In addition, ASME B16.36 standardizes the orifice flange, which only starts at 900 #.