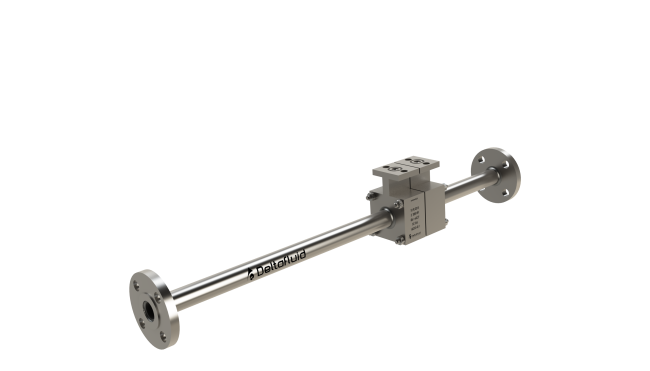

Complete measuring element with special flanges - Suitable for pipe diameters ≤ 40 mm

GENERAL DATA

- Standards: ASME MFC-14M.

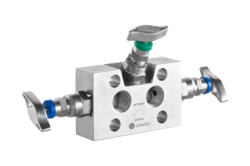

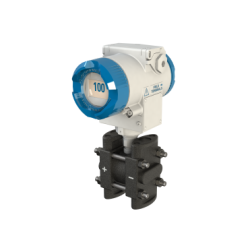

- Installation of the integrated sharp-edge orifice plate: between special flanges (direct mounting of the manifold and the differential pressure transmitter)

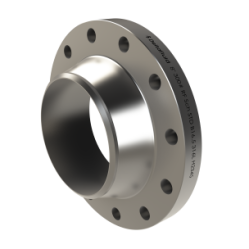

- Solder (BW) or flanged connection

- Material: Standard: carbon steel, stainless steel, others according to your application.

- Fluid: liquid, gas, steam.

- Diameter of pipes: from 6 to 40 mm.

- Overall measurement accuracy: 0.5% of max flow.

- Repeatability of the measure: 0.1%

| ASME MFC-14M | ||

|---|---|---|

| ReD | Reynolds number in pipework | ReD > 1 000 |

| D | Pipe interior diameter | 6 mm ≤ D ≤ 40 mm |

| β | d/D | 0,1 ≤ β ≤ 0,8 |

| Plaque à arête vive | ||

|---|---|---|

| Ra | Roughness of the upstream face plate | Ra < 1,27 μm |

| r | Sharp edge radius | r < 0,000 4.d ou(1) 0,025 μm |

| e | Orifice thickness | e < 0,02.D ou(1) 0,125.d |

| E | Plate tickness | E < 3,2 mm |

| α | Downstream bevel angel | α = 45° ± 15° |

| t | Flatness tolerance | t < 0,01.(D - d)/2 |

(1) take the smaller of the two values

An integrated orifice meets the ASME MFC-14M standard for flow measurement in pipework from 6mm in diameter and offers a complete set with differential pressure primary element and upstream and downstream straight lengths for optimum measurement accuracy. It is equipped with special flanges for direct mounting of the transmitter.

If you do not find the answer you are looking for, please contact us either by phone at +33 (0)5.59.30.85.20 or via the contact form. We will respond as soon as possible.

According to ASME MFC-14M, an integrated orifice is a complete flow measuring device: it includes the primary measuring element (orifice plate), the special flanges, the corner pressure taps (0/0) and upstream and downstream straight lengths. It is designed to fit directly on small pipes up to DN 40.