Recommended orifice plate for dirty, charged or two-phase fluids

GENERAL DATA

- Standard: ISO / TR 15377.

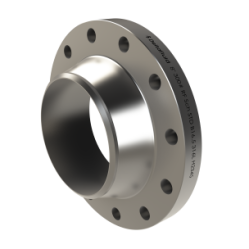

- Mounting between flanges: ISO PN 2,5 to PN 420, ASME 150 # to 2500 #, others on consultation.

- Material: Standard: 304L / 316L stainless steel, others according to your application.

- Fluid: liquid, gas, steam.

- Diameter of pipes: from 100 to 1000 mm.

- Accuracy: 1% of max flow.

- Repeatability of the measurement: 0.1%.

- Pressure taps: in the corners.

| ISO/TR 15377 | ||

|---|---|---|

| ReD | Reynolds number in pipework | 42 000 ≤ ReD ≤ 8,4.105 |

| D | Pipe interior diameter | 100 mm ≤ D ≤ 1 000 mm |

| d | Orifice diameter | d ≥ 50 mm |

| β | d/D | 0,46 ≤ β ≤ 0,84 |

| Ra | Upstream face roughness | Ra < 10⁴.d |

| r | Sharp edge radius | r < 0,000 4.d |

| e | Eccentric orifice thickness | 0,005.D ≤ e ≤ 0,02.D |

| E | Plate thickness | e ≤ E ≤ 0,05.D |

| α | Downstream bevel angle if necessary | α = 45° ± 15° |

| t | Flatness tolerance | t < 0,005.(D - d)/2 |

If you do not find the answer you are looking for, please contact us either by phone at +33 (0)5.59.30.85.20 or via the contact form. We will respond as soon as possible.

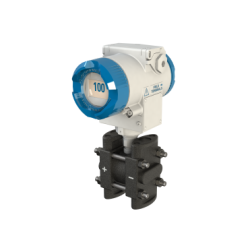

An eccentric plate, as the name suggests, has an orifice placed not in the center of the pipe (like a sharp edge plate for example) but an eccentric orifice. It is positioned so that the outer part of the orifice is tangent with the piping at the bottom; thus, no dirt can accumulate at this point and clog the flowmeter.

The choice between an eccentric plate and a segmental plate is made by calculation according to the characteristics of the fluid. Pipe diameters and Reynolds number ranges differ slightly from one plate to another.

To understand and choose from the different orifice plates, refer to the selection table.