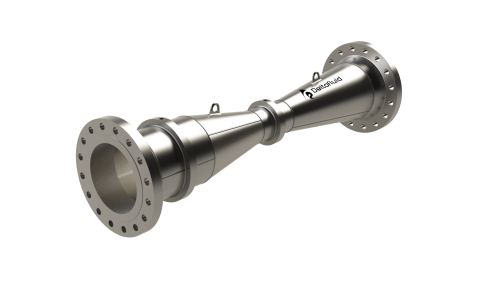

Rolled-welded Venturi

Suitable for large diameters and / or low permanent pressure drop

GENERAL DATA

- Standards: ISO 5167-1 & 4, ASME MFC-3M.

- Solder (BW) or flanged connection

- Material: Standard: carbon steel, stainless steel, others according to your application.

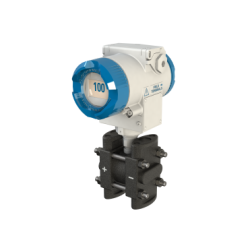

- Fluid: liquid, gas, steam.

- Diameter of pipes: from 100 to 1,200 mm.

- Accuracy: 1.5% of max flow.

- Repeatability of the measurement: 0.1%.

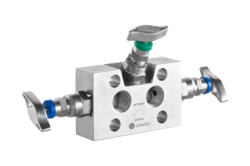

- Upstream and neck pressure points: annular chamber or individual plugs connected in "triple T".

| ISO 5167-1&4 | ASME MFC-3M | ||

|---|---|---|---|

| ReD | Number of Reynolds in pipeline | 2.105 ≤ ReD ≤ 2.106 | 2.105 ≤ ReD ≤ 6.106 |

| D | Pipe interior diameter | 200 mm ≤ D < 1 200 mm | 100 mm ≤ D ≤ 1 200 mm |

| β | d/D | 0,40 ≤ β ≤ 0,70 | 0,30 ≤ β ≤ 0,75 |

| Ra | Roughness at the throat | Ra ≤ 10⁴.d | |

| Input cylinder and convergent roughness | Ra ≤ 5.10⁴.D | ||

| l | Minimum inlet cylinder length | l = D | |

| l' | Minimum inlet cylinder length | l' = 2,7.(D - d) | |

| α | Convergent angle of entry | α = 21° ± 1° | |

| lc | Throat length | lc = d ± 0,03.d | |

| φ | Diverging angle of exit | 7° ≤ φ ≤ 15° | |

You can find below our most frequently asked questions / answers.

If you can not find the answer you are looking for, please contact us either by phone at +33 (0)5.59.30.85.20 or via the contact form. We will respond as soon as possible.

How is a rolled venturi tube made?

This venturi model is made from sheet metal that is rolled into convergent, divergent and cylinder (throat) shapes. These sheets are then welded together to form the venturi. Welds are checked radiographically most often (weld seam node control and longitudinal control) to ensure that there are no defects.