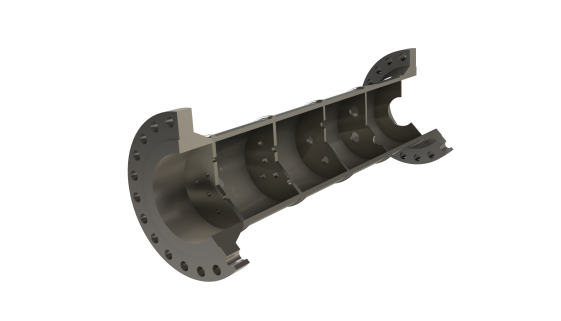

Multiple plates in series when the desired pressure drop can not be reached with a single plate

GENERAL DATA

- Standards: Element based on R.W. MILLER or ISO 5167. Possible design according to Idel'cik (orifices with rounded or beveled edges).

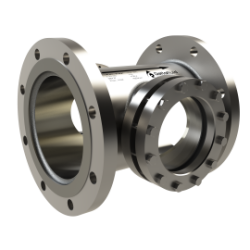

- Solder (BW) or flanged connection

- Material: Standard: 304L / 316L stainless steel, others according to your application.

- Fluid: liquid, gas, steam.

- Diameter of pipes: all sizes.

- Plate mounting: plates mounted in serie - optimized plate spacing for each unit from 1D to 5D (D, pipe internal diameter).

- Number of plates: calculation of the number of stages optimized according to the specifications of the application, each plate making it possible to reduce the maximum pressure while avoiding cavitation and critical flow phenomena.

WHAT IS CAVITATION AND CRITICAL REGIME AND HOW TO AVOID THEM?

- Noise: check of the noise level of the complete unit estimated at 1 m. Multi-holes plates reduce the noise level per stage.

FIND OUT HOW TO LIMIT THE NOISE LEVEL when passing through the restriction.

Solutions of external envelopes can be recommended if the noise remains too high (consult us).

- Thermodynamics: the thermodynamic properties of the fluid are taken into account for the calculation of each stage: change of state, temperature, composition and density of the mixture, viscosity, compressibility factor.

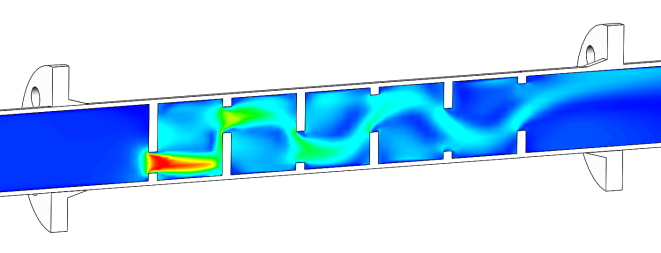

- 3D simulation: possibility of a numerical simulation to complete the analytical calculations.

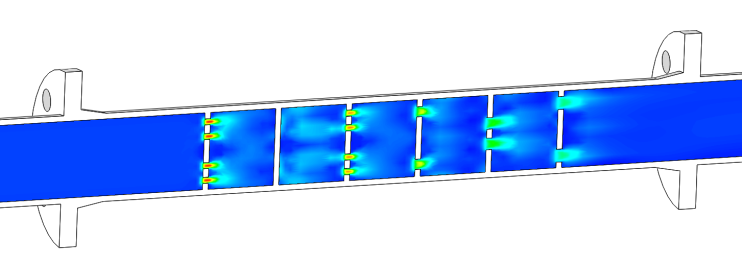

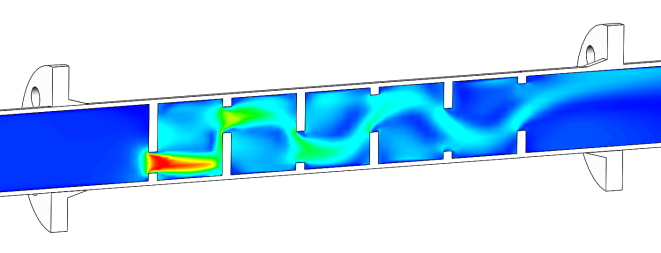

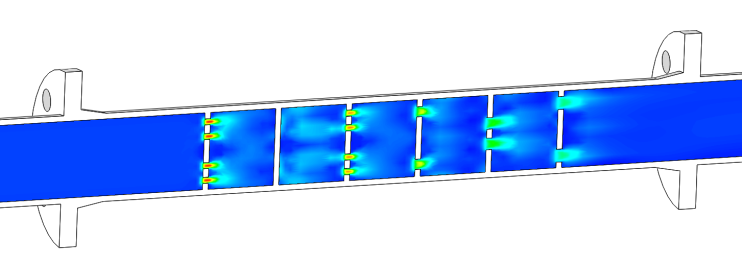

Example: validation of the design of a restriction orifice after comparison of the speeds at the passage of the restrictions

Fluid velocity with single orifice plates

Fluid velocity with multi-orifice plates

If you do not find the answer you are looking for, please contact us either by phone at +33 (0)5.59.30.85.20 or via the contact form. We will respond as soon as possible.

A multi-stage restriction orifice (several plates in serie) instead of a simple restriction orifice is used if the desired pressure drop can not be achieved with a single plate. Indeed, each plate / stage enables reducing the pressure to its maximum while avoiding the phenomena of cavitation (for liquids) and critical regime (choked flow for gases or choking cavitaiton for liquids).

BETTER UNDERSTAND THESE PHENOMENA

The calculation of the number of plates / stages is therefore a function of the data of your application.

We have developed an internal software called SIZEWELL which allows us to quickly know the number of stages needed based on your process data; this information is interesting when you need to estimate the length of your devices.

Please, go to the SIZEWELL tool, provide all the information related to your fluid and your installation and validate your project. We will then receive your data and be able to provide you with our results as soon as possible.

Do not hesitate to contact us directly for more responsiveness.

The number of stages can vary from 1 to more than 10 if necessary. It is dictated by the pressure drop to be reached. Usually, the more the pressure drop is important, the more the number of stages to reach it is important.

We have developed an internal software called SIZEWELL which allows us to quickly know the number of stages needed based on your process data; this information is interesting when you need to estimate the length of your devices.

Please, go to the SIZEWELL tool, provide all the information related to your fluid and your installation and validate your project. We will then receive your data and be able to provide you with our results as soon as possible.

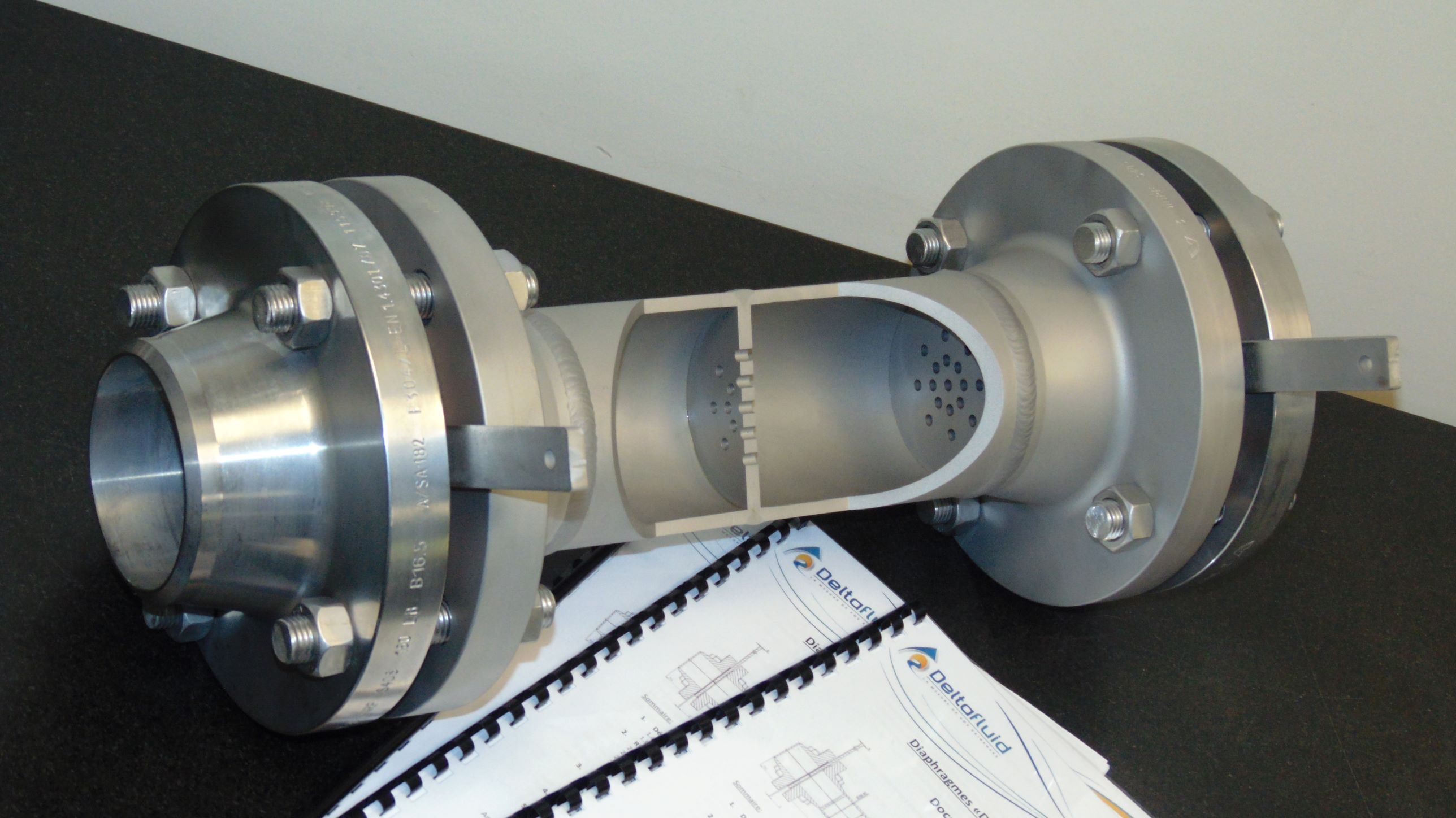

To better understand how it works, we have developed cross-sectional demonstration models.

This way, our customers can easily train their internal teams, particularly their installers, who are aware of the necessary information before carrying out operations on site.

These models are delivered with a technical product presentation file which details:

- the applicable standards,

- the risks linked to specific phenomena such as cavitation, flashing, critical flow, noise levels, etc. and the corresponding solutions.

LEARN MORE ABOUT THESE PHENOMENA - the different types of existing restriction orifices: simple, multi-hole or multi-stage

- mounting and orientation of the device on the pipe

- examples of problem solving

- ...

To optimize the design of the device and complete / validate the analytical calculations, our design office is able to carry out 3D fluid flow simulations as presented below.

Example : validation of the design of a restriction orifice after comparison of speeds passing through the restrictions

Fluid velocity with single hole orifice plates

Fluid velocity with multi-hole orifice plates

This step is not mandatory but may be necessary for specific applications. Our project managers will be able to advise you best.