For a direct reading of temperature

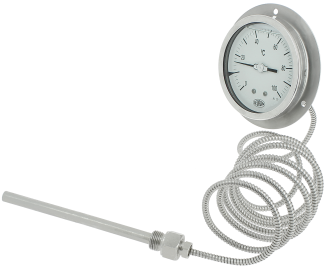

We offer thermometers with expansion of liquid or gas:

GENERAL DATA

- Standard: EN13190

- Remote measurement with capillary or direct measurement

- Element of measurement: rigid bulb.

- With or without thermowell

As well as bimetallic thermometers:

GENERAL DATA

- Standard: EN13190

- Element of measurement: bimetallic element.

- With or without thermowell

| Expansion thermometer | Bimetallic thermometer | ||

|---|---|---|---|

| Measuring scale | -200°C to +700°C | -70°C to +600°C | |

| Dial diameter | 100 mm - 150 mm | ||

| Housing | stainless steel | ||

| Immersion | stainless steel | ||

| Diameter of the immersion | until 12 mm | ||

| Useful length of the immersion | until 300 mm | until 1000 mm | |

| Capillary length | until 10 m | - | |

| Type of process connection | Screwed | ||

| IP protection rating | up to IP66 | ||

| Accuracy | Class 1 or 2 regarding EN 13190 | ||

If you do not find the answer you are looking for, please contact us either by phone at +33 (0)5.59.30.85.20 or via the contact form. We will respond as soon as possible.

A dilatation thermometer is the only one to possess a capillary containing a liquid or a gas whose volume varies under the effect of a variation of temperature driving the dial pointer. Thus, the dial can be installed remote from the bulb (remote measurement up to 10 m standard - higher distance on request) which helps reaching sometimes inaccessible places. More over, it works for a temperature measurement range from -200°C to + 700°C.

A bimetallic thermometer has a helicoidal bimetal located at the back of the dial and acting directly on the indication pointer. It therefore has no capillary and the temperature is read on the dial directly at the place where the temperature is measured. The measuring range is -70°C to + 600°C. The ambient temperature has no influence on the bimetallic thermometer measurement.

In addition, by comparison, the response time of a dilation thermometer is lower than that of a bimetallic thermometer. Indeed, the change in volume and therefore the pressure of the gas in the capillary is instantaneous during a change of temperature while the deformation of the metal helicoid takes a little longer. But the response time is also related to the thermowell in which the bulb sensor is placed and to the size of the bulb; it is therefore necessary to choose it carefully.