Orifice plate

The most standardized cost-saving solution for a DP flowmeter

Orifice plates or diaphragms are the most commonly used primary elements for differential pressure flow measurement. They allow measurement over a wide range of flow rates and for a wide range of pipe diameters. There are several types: the sharp-edge orifice plate, the best known, the other concentric plates with conical inlet and quarter circle plate for the measurement of low flows or viscous fluids and the eccentric plate or segmental plate for the measuring dirty or impure fluids. Finally, the multi-hole / conditioning orifice plate allows a measure of quality while providing a minimum footprint.

Inserted within a circular pipe, they create an obstacle, increase the speed of the fluid and generate a pressure difference between upstream and downstream of the restriction. This differential pressure measurement is proprotional to the flow rate value.

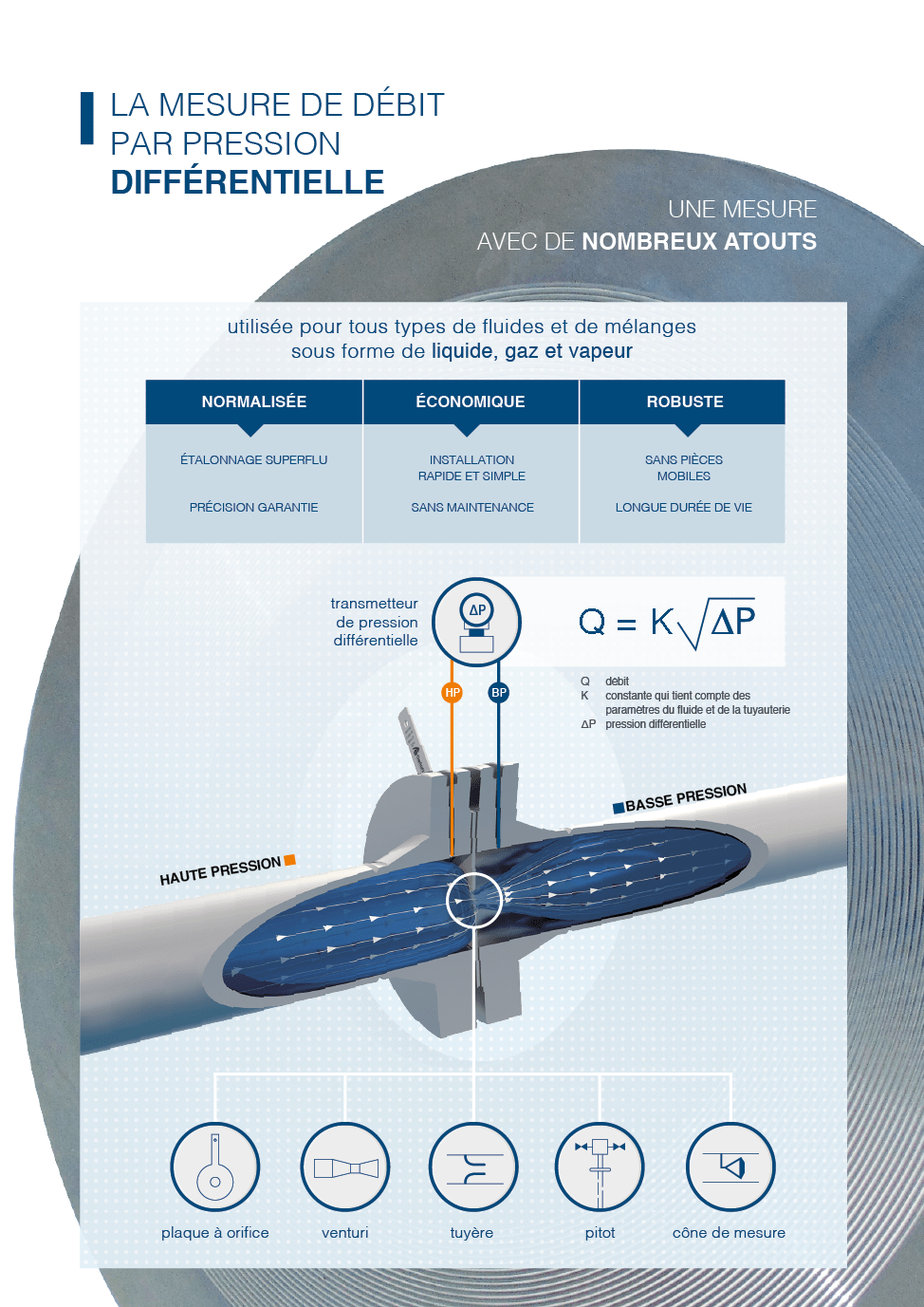

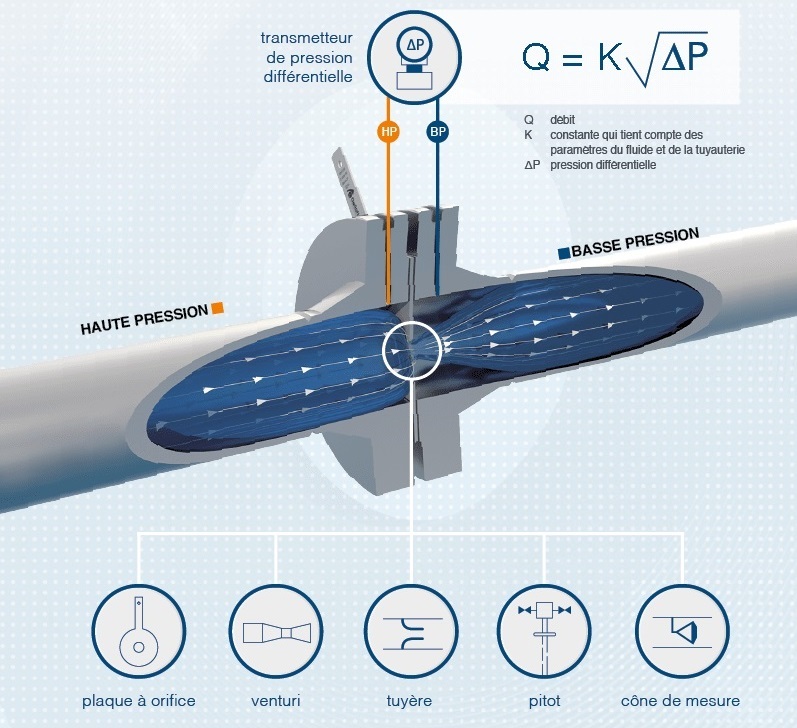

The principle of the flow measurement by differential pressure is to insert in a circular pipe a restriction which generates a pressure difference between the upstream and the downstream of this restriction.

The measurement of this pressure difference (called ΔP) is transformed by a differential pressure sensor into a 4-20 mA signal and then translated into a flow rate according to the law:

Q being the flow

K a constant that takes into account the fluid parameters, the viscosity, the roughness of the pipework, the density of the fluid, etc.

Δp the differential pressure (upstream pressure - downstream pressure).

The differential pressure element considered here is the orifice plate.

There are other types more or less adapted to the characteristics of your process. It's about choosing the best solution in terms of measurement quality, size and price. That is why we are at your disposal to provide you all the information on this subject and help you in your selection.

This table is a tool to help select the flow measurement primary element.

Depending on the type and characteristics of the fluid to be measured, you will have a first idea of the orifice plate adapted to your application.

Attention, as any first approach, it is imperative to validate the choice by a calculation made by our specialized design office.

For the calculation, we need information about your process.

If you do not find the answer you are looking for, please contact us either by phone at +33 (0)5 59 30 85 20 or via the contact form. We will respond as soon as possible.

The orifice plate (or other flow measurement primary element such as venturi, nozzle ...) creates a restriction in the pipe.

This restriction accelerates the fluid and creates a slight depression.

It is enough to know the upstream (HP high pressure) and downstream pressure value (BP low pressure) of the restriction to be able to calculate the flow that passes through the pipe thanks to the Bernoulli equation. Of course, the orifice plate is standardized and its design and manufacture follow strict criteria so that the measurement is as accurate as possible.