To stabilize a flow in a pipe upstream of a measuring element

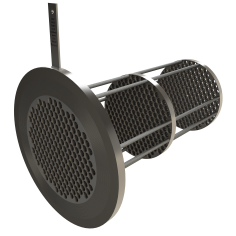

A flow straightener greatly reduces disturbances in a flow while a conditioner reduces disturbances and also allows a good redistribution of the speed profile, at each point of the section of the pipe.

Thus, these devices make it possible to reduce the upstream straight lengths and to improve the measurement accuracy in the case of a flow measurement. They are therefore to be positioned between a pipe fitting (elbow, reduction, etc.) and a flow measurement element while respecting the distances specified in the standard.

MAIN FEATURES

- Standard: ISO 5167, ASME MFC-3M.

- Fluid: liquid, gas, steam.

- Solder (BW) or flanged connection

- Different types: tube bundleflow straightener, AMCA or "Star" straightener, Gallagher, K-Lab Nova, NEL, Sprenkle or zanker flow conditioner.

If you do not find the answer you are looking for, please contact us either by phone at +33 (0)5 59 30 85 20 or via the contact form. We will respond as soon as possible.

The flow straightener / conditioner is positioned between the upstream reduction and the primary flow measurement element in order to reduce the straight length.

Example: in the case of an orifice plate of β = 0.5 and for a single bend at 90 °, the upstream straight length to be respected without flow conditioner is 22.D (22 times the inside diameter of the line). With a 19-tube bundle flow straightener, the recommended straight length is only 13.D.

These recommended straight lengths are mentioned in the corresponding standard and depend on the primary element considered and the ratio of diameters β. We will be able to advise you according to your application.

Several solutions exist to reduce the total straight length necessary for the purpose of installing a differential pressure flowmeter. Here is a non-exhaustive list of these solutions:

1. Flow straightener / conditioner: this item considerably reduces the disturbances caused by the upstream accessory and thus improves the measuring accuracy and reduces the required straight lengths. The characteristics of these devices are described and listed in the ISO5167 standard. See question above for an estimation of the reduction in straight length.

2. Multi-hole plate: this is the economical solution for reducing upstream and downstream straight lengths. Indeed, a minimum distance of 2xD (upstream and downstream) is recommended between the primary element and the pipe fittings. This DP element has been the subject of extensive experiments and is already used in many applications but it is not standardized to date.

3. Venturi tube: this device has a particular geometry that helps to reduce the irregularities of the flow; thus, the required straight lengths are reduced compared to an orifice plate for example (for β = 0.5 and a simple 90 ° elbow upstream, the straight length required for an orifice plate is 22xD while is 9xD for a venturi tube). Its price is however higher than an orifice plate.

4. Cone meter: the straight lengths required to install a cone meter are reduced (3xD upstream and 2xD downstream). But the uncertainty on the discharge coefficient is 5% while it can reach 0.5% for an orifice plate. A specific calibration can be proposed to improve the measurement accuracy.

Each of the characteristics of your process is to be studied to choose the best solution in terms of measurement quality, size and price. That is why we are at your disposal to provide you with additional information and help you in your selection.

The ISO5167 standard defines these two products:

a straigntener considerably reduces the disturbances in a flow while a conditioner reduces the disturbances and also allows a good redistribution of the speed profile, at each point of the section of the pipe.

The standard presents different types of devices and gives their characteristics:

- flow straignteners: tube bundle flow straightener, AMCA and Star straightener

- flow conditioners : Gallagher, K-Lab NOVA, NEL (Spearman), Sprenkle and Zanker conditioners