For a more stable and precise averaged pressure measurement

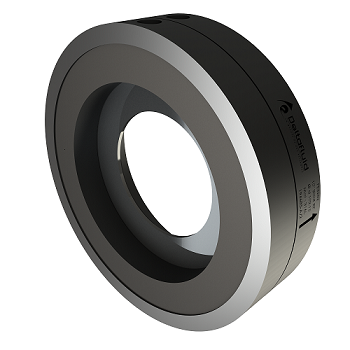

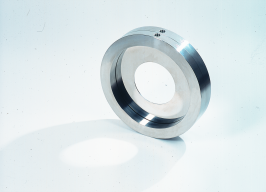

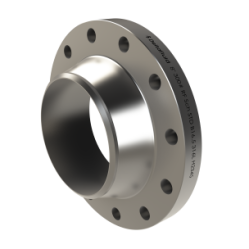

The annular chamber (carrier rings) is proposed for orifice plates, for venturis and for nozzles.

It has several advantages: it favors the circulation of the fluid over the complete circumference of the pipework and offers a more stable and precise averaged pressure; in the case of the orifice plate, it also allows to change only the plate in case of maintenance or change of process compared to a monoblock where the complete system must be changed.

This type of mounting is particularly recommended for pipe diameters smaller than DN50.

For the technical characteristics of the measuring orifice, refer to the datasheet of the selected element (sharp-edge, conical, quarter-circle, eccentric, segmental or multi-hole orifice plate, machined venturi, welded venturi or venturi "as cast", ISA1932 nozzle or venturi-nozzle).

If you do not find the answer you are looking for, please contact us either by phone at +33 (0)5.59.30.85.20 or via the contact form. We will respond as soon as possible.

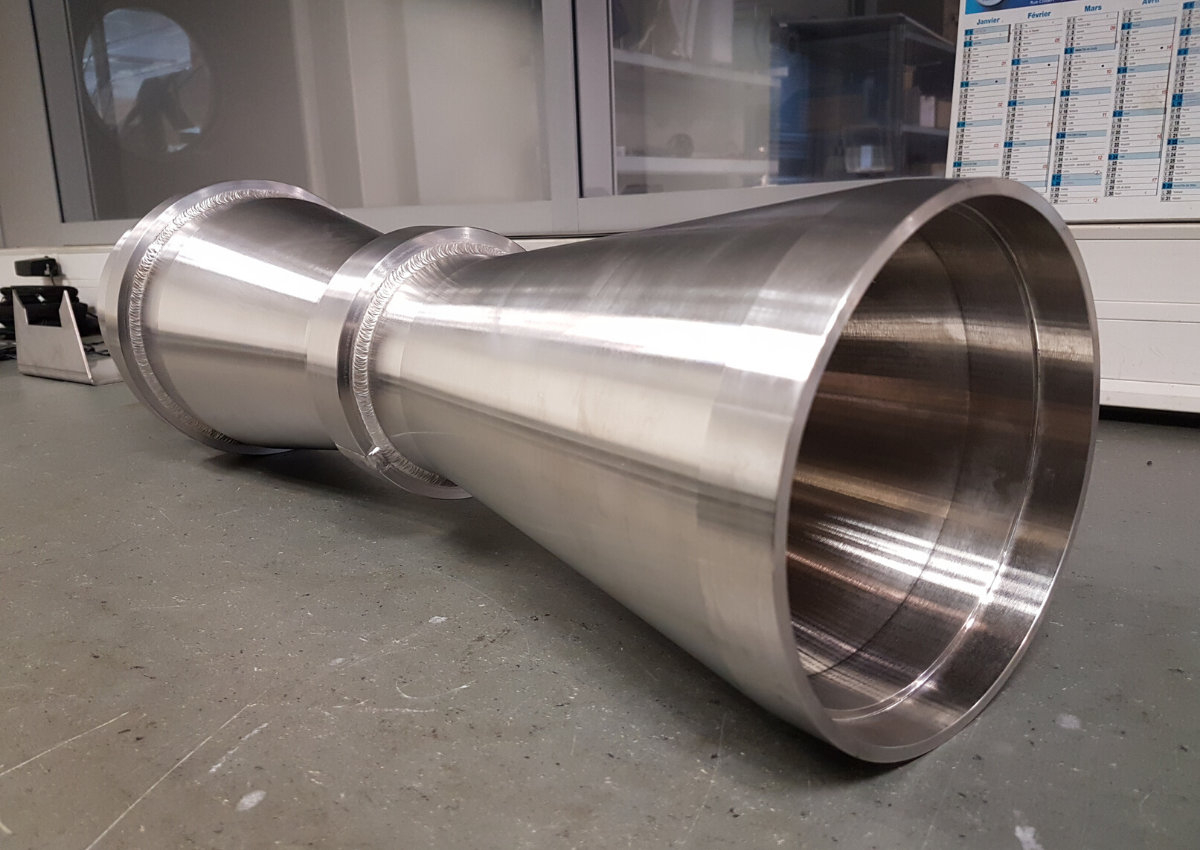

For venturi tubes, whether they are machined, welded or cast, and for the venturi-nozzle, the standard provides for the upstream and throat pressure taps to be in the form of an annular chamber or with individual taps connected to each other in "triple T".

For the ISA1932 nozzle, the pressure taps must be in the corners (0/0). The assembly with annular chamber is therefore particularly suitable.

For orifice plates, this mounting is often proposed for diameters smaller than DN50 so as to allow an average of the upstream and downstream pressure and to have a 0/0 pressure tap with mounting between single flanges.