Instrumentation accessory for setting and commissioning the measuring instrument

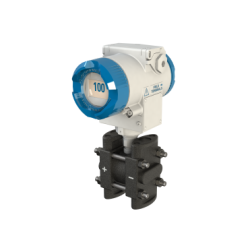

A manifold is mounted to the interface between the pressure taps and the transmitter. It is used to isolate the transmitter in case of intervention on the pipe. It also allows you to reset the zero of the transmitter or purge the impulse taps.

MAIN FEATURES

- Material: Standard: carbon steel, 304L / 316L stainless steel, others according to your application.

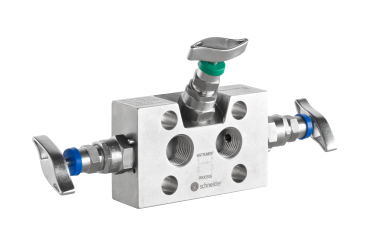

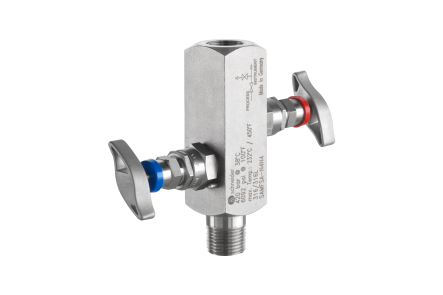

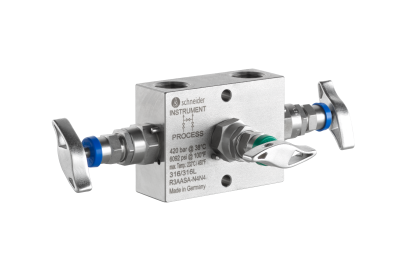

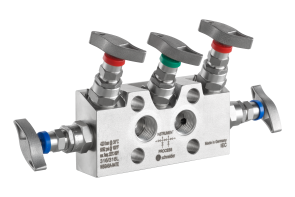

- 2, 3 or 5 ways

- Transmitter interface according to EN61518 standard

If you do not find the answer you are looking for, please contact us either by phone at +33 (0)5 59 30 85 20 or via the contact form. We will respond as soon as possible.

A 2-way manifold is suitable for a relative or absolute pressure transmitter. It isolates the transmitter to purge the impulse line if necessary.

The 3 or 5 way manifolds are mounted on the differential pressure transmitters. The 3 channels are used to isolate and re-parameterize the zero of the transmitter. The 2 additional channels are used to purge the impulse taps.

Direct mounting is when the transmitter is directly mounted and screwed onto the manifold.

In contrast, it is sometimes necessary to position the transmitter away from the manifold (to centralize several transmitters for example or to have the transmitter display at a given location). Thus, impulse taps connect the manifold to the transmitter. This is called remote mounting.

There is a particular case of direct mounting: the compact flowmeter. In this extremely compact product, the built-in impulse taps are directly connected to the manifold on which the transmitter is mounted. The device, 100% factory-tested, eliminates all risks of leakage and offers the advantage of reduced installation, commissioning and maintenance costs.