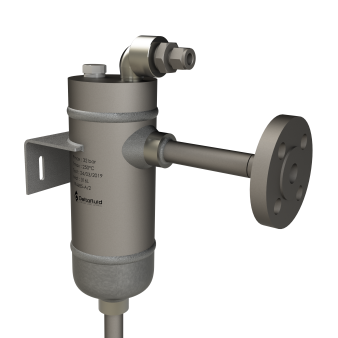

In steam applications, transmitter protection element for accurate pressure measurement

For steam applications, condensate pots are essential. They are used to condense the fluid upstream of the differential pressure transmitter and thus protect it on a thermal point of view. Installed at the same height, they allow accurate measurement by maintaining a constant condensate height in the impulse lines above the differential pressure transmitter.

The condensation pot can also be used to protect the transmitter in the case of a flow measurement of a corrosive / aggressive fluid. In this case we speak of separation pots.

For more information, see the Frequently Asked Questions tab on this page.

MAIN FEATURES

-

Volume : from 0,5 to 5 liters

-

Number of connections : up to 6 taps

-

Types of connection : 1/4'' fem. NPT, 1/2'' fem. NPT, 1'' fem. NPT, 1/4'' BSPT, 1/2'' BSPT, 1/2'' 600# RF, 1/2'' 600# RTJ, others

-

Material : Standard : stainless steel 304L / 316L / Others according to your specification (Carbon Steel, 16Mo-F11/P11, 6Mo...)

- Directive: Pressure Equipment Directive PED 2014/68/EU depending on the volume considered. Condensation pots with a volume of less than 1 liter are subject to the PED Art 4.3 directive, which does not require specific test.

CONDENSATION POTS IN STOCK

-

Pots in 3", schedule 80, volume 1.0 litre, 4 1/2" NPT-F connections, in carbon steel

-

Pots in 3", schedule 40, volume 1.0 litre, 4 1/2" NPT-F connections, in Stainless Steel 316L

-

These items in stock can be delivered quickly; contact us.

If you do not find the answer you are looking for, please contact us either by phone at +33 (0)5 59 30 85 20 or via the contact form. We will respond as soon as possible.

- The condensate pot is mandatory for accurate measurement in the case of steam applications. It is used to condense the steam systematically upstream of the transmitter; it thus maintains a constant condensate height in the impulse lines above the differential pressure transmitter; it therefore allows an accurate measurement of the differential pressure. Without a condensation pot, the vapor would condense randomly along the impulse lines to the transmitter (depending on the temperature drop undergone) and cause a differential pressure measurement error.

- The separation pot can be used to protect the differential pressure transmitter in the case of a flow measurement of a corrosive and high-density fluid.

It is filled with a buffer liquid (fluid A), in contact with the membrane of the transmitter to ensure the transmission of pressure, and immiscible with the high density fluid of the process (fluid B). The difference in density of the two fluids and the fact that they are immiscible allow a real separation between the transmitter side and the process side.

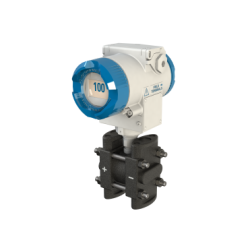

Another way to prevent the transmitter diaphragm from contact with the process fluid is to use a capillary with the transmitter.