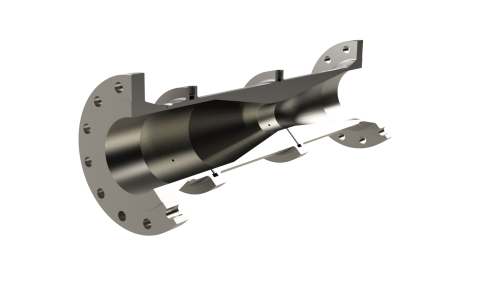

Machined Venturi

Suitable for small diameters and / or low permanent pressure drop

GENERAL DATA

- Standards: ISO 5167-1 & 4, ASME MFC-3M.

- Solder (BW) or flanged connection

- Material: Standard: carbon steel, stainless steel, others according to your application.

- Fluid: liquid, gas, steam. Diameter of pipes: from 50 to 250 mm.

- Accuracy: 1% of max flow.

- Repeatability of the measurement: 0.1%.

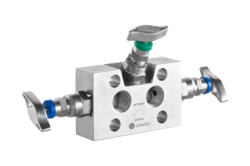

- Upstream and neck pressure points: annular chamber or individual plugs connected in "triple T".

| ISO 5167-1&4 | ASME MFC-3M | ||

|---|---|---|---|

| ReD | Reynolds number in pipework | 2.105 ≤ ReD ≤ 106 | 2.105 ≤ ReD ≤ 6.106 |

| D | Pipe interior diameter | 50 mm ≤ D ≤ 250 mm | |

| β | d/D | 0,40 ≤ β ≤ 0,75 | 0,30 ≤ β ≤ 0,75 |

| Ra | Roughness at the throat | Ra ≤ 10⁴.d | |

| Input cylinder and convergent roughness | Ra ≤ 10⁴.d | ||

| l | Minimum inlet cylinder length | l = D | |

| l' | Convergent input length | l' = 2,7.(D - d) | |

| α | Convergent angle of entry | α = 21° ± 1° | |

| lc | Throat length | lc = d ± 0,03.d | |

| φ | Diverging angle of exit | 7° ≤ φ ≤ 15° | |

You can find below our most frequently asked questions / answers.

If you do not find the answer you are looking for, please contact us either by phone at +33 (0)5.59.30.85.20 or via the contact form. We will respond as soon as possible.

In which cases choose a machined or rolled welded venturi?