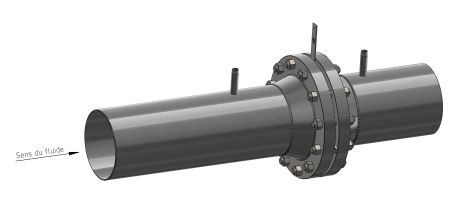

Flowmeter with pressure taps located at 1D upstream and D/2 downstream of the measuring element

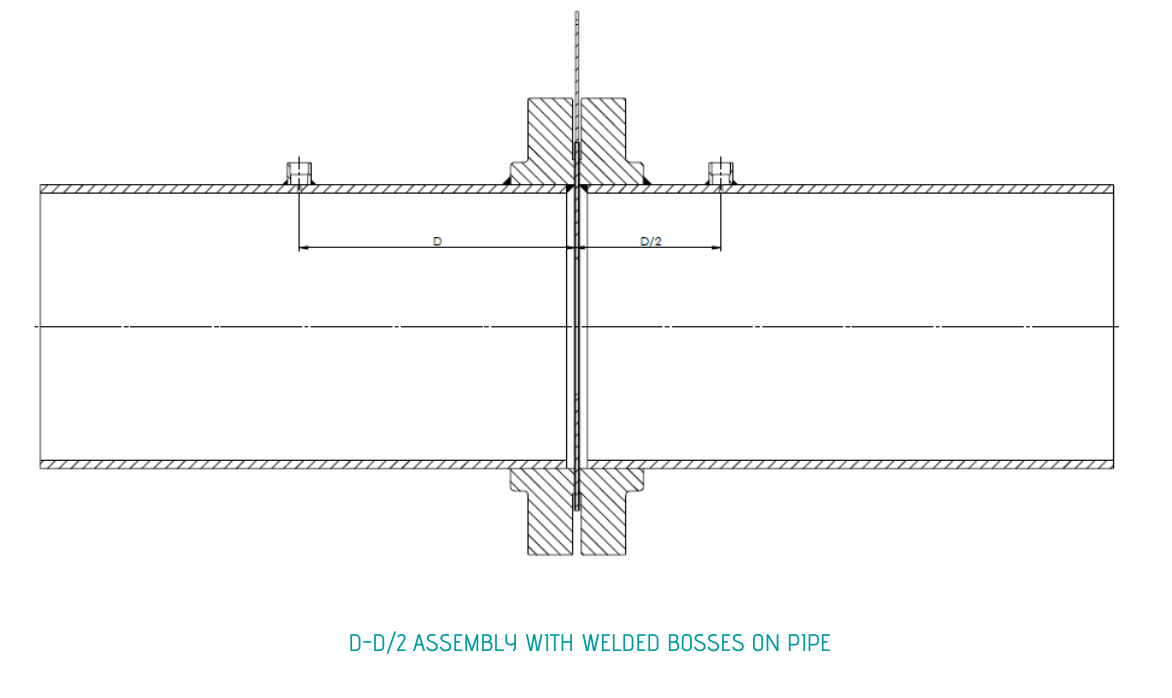

According to ISO 5167, flowmeters with orifice plates and nozzles (long radius) can benefit from D - D/2 mounting. This corresponds to a positioning of the upstream tap at a distance of 1D (D, internal diameter of the pipework) from the upstream of the orifice plate and the downstream tap at a distance of 1/2D from the downstream of the plate.

This type of assembly has the advantage of not requiring orifice flanges (more expensive than standard flanges): you simply prepare bosses on the piping upstream and downstream of the measurement to position the pressure taps. It is widely used for large pipe diameters.

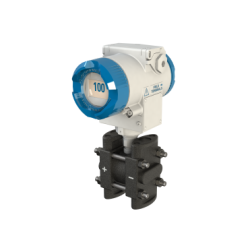

A D - D/2 flowmeter is a differential pressure flowmeter with pressure taps positioned at 1D upstream and 1/2D downstream of the measuring element. Its characteristics depend on those of the measuring element considered, the orifice plate or the long radius nozzle. For details on the characteristics, refer to the datasheet of the orifice plate or the one of the nozzle.

If you can not find the answer you are looking for, please contact us either by phone at +33 (0)5 59 30 85 20 or via the contact form. We will respond as soon as possible.

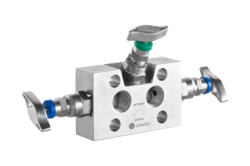

For an explanation of the types of pressure taps and their use, see further details.