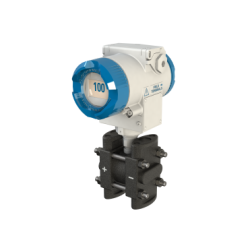

Economical solution thanks to the reduction of upstream and downstream straight lengths

GENERAL DATA

- Standard: Element designed on the basis of ISO 5167-1 & ISO 5167-2 or ASME FC-3M.

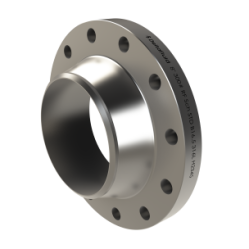

- Mounting between flanges: ISO PN 2,5 to PN 420, ASME 150 # to 2500 #, others on consultation.

- Material: Standard: 304L / 316L stainless steel, others according to your application.

- Fluid: liquid, gas, steam.

- Diameter of pipes: from 25 to 1000 mm.

- Accuracy: 0.5% of max flow.

- Repeatability of the measurement: 0.1%.

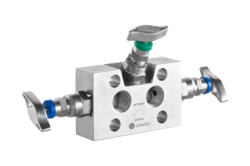

- Pressure taps: in the corners, at the flange.

| ReD | Reynolds number in pipework | 5 000 ≤ ReD ≤ 108 |

| D | Inner diameter of pipe | 25 mm ≤ D ≤ 1 000 mm |

| d | Orifice diameter | d ≥ 6 mm |

| β | d/D | 0,2 ≤ β ≤ 0,65 |

| Ra | Upstream face roughness | Ra < 10⁴.d |

| r | Sharp edge radius | r < 0,000 4.d |

| e | Sharp edge orifice thickness | 0,005.D ≤ e ≤ 0,02.D |

| E | Plate thickness | e ≤ E ≤ 0,05.D |

| α | Downstream bevel angle if needed | α = 45° ± 15° |

| t | Flatness tolerance | t < 0,005.(D - d)/2 |

If you do not find the answer you are looking for, please contact us either by phone at +33 (0)5.59.30.85.20 or via the contact form. We will respond as soon as possible.

A multi-hole orifice plate (or conditioning orifice plate) behaves like a flow conditioner. In addition to allowing flow measurement, it stabilizes the flow and thus requires reduced upstream and downstream straight lengths compared to other orifice plates. It is therefore used for footprint issues mainly.

It should be noted that these orifice plates are based on existing standards but are not standardized. They have been thoroughly tested to conclude on their proper operation and accuracy of measurement.

To understand and choose from the different orifice plates, refer to the selection table.